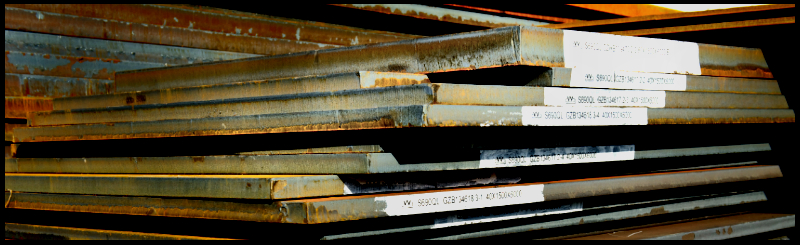

S690QL High Strength Quenched and Tempered Structural Steel

EN10025 S690QL Structural Steel

EN10025:6:2004 Hot Rolled S690QL, Steel Number 1.8928. 690 N/MM2 high yield, high strength structural steel plate,V notch impact tested in longitudinal direction to the rolling direction at -40degree C, thus being excellent in forming and draculalespectacle welding properties that achieve another higher level of beauty and durability in steel engineering structure. S690QL steel plates are used in high stress applications while weight saving is crucial at the same time. This high strength steel is ideal application for cranes, jack up rigs, lifting equipments, mining equipments and facilities, earthmoving equipments, agricultural equipments, bridges, trailers, theme park rides and facilities, military equipments and facilities, search and rescue operation equipments and where the why not try here Toothache Buy Soma engineering design need lighter weight with increase payload capacity and energy efficiency.

690 N/MM2 high yield strength other product such as EN10210 Hot Finished S690 Hollow Sections - Seamless RHS, SHS, CHS, Elliptical, Half-Elliptical, Flat-Oval, Octagonal, Hexagonal and Triangular are available.

S690QL Grade Designation

• S = Structural Steel

• 690 = minimum yield strength (MPa)

• Q = Quenching & Tempering

• L = Low notch toughness testing temperatures

Condition of Delivery

Water quenched and https://cholesterolerectiledysfunction.com/pneumothorax-ventolin.html tempered.

S690QL Chemical Composition

|

C |

Si |

Mn |

P |

S |

B |

Cr |

Cu |

Mo |

|

0.20 |

0.80 |

1.70 |

0.020 |

0.010 |

0.005 |

1.50 |

0.50 |

0.70 |

|

N |

Nb* |

Ni |

Ti* |

V* |

Zr* |

|||

|

0.015 |

0.06 |

2.0 |

0.05 |

0.12 |

0.15 |

* There shall be at least 0.015% of a grain-refining element present. Aluminium is also one of these elements. The 0.015% applies to soluble aluminium, this value regarded as attained if the total aluminium content is at least 0.018%

Please note :The manufacturer reserves the right to change the chemical composition.

CEV = C + Mn/6 + (Cr+Mo+V)/5+(Cu+Ni)/15

S690QL High Strength Quenched and Tempered Structural Steel

S690QL Mechanical Properties

|

Plate Thickness |

Yield Strength |

Tensile Strength |

Elongation |

|

MM |

ReH(Mpa) |

Rm(Mpa) |

A5% Minimum |

|

3 to 50 |

690 |

770~940 |

14 |

|

> 50 to 100 |

650 |

760~930 |

14 |

|

> 100 to 150 |

630 |

710~900 |

14 |

S690QL V Notch Impact Test

|

Position of Samples |

0 degree C |

- 20 degree C |

-40 degree C |

|

Longitudinal |

50 Joules |

40 Joules |

30 Joules |

|

Transverse |

35Joules |

30 Joules |

27 Joules |

Processing of S690QL High Strength Steel Plate

S690QL Cold Forming

S690QL steel plate is suitable for cold-forming adhering to a bending or folding radius > 4 times steel plate thickness longitudinal and > 3 times transverse to rolling direction. A subsequent stress relief annealing is possible up to a temperature of 580 ºC (degree C).

|

Minimum recommended inside bending radius |

|

|

Axis of bend in transverse direction 3.0t |

Axis of bend in longitudinal direction 4.0t |

S690QL Hot-Forming

Hot-forming above 580°C is possible. A subsequent quenching and tempering has to be carried out according to the conditions of delivery.

S690QL Milling

Drilling with cobalt-alloyed high-speed steels HSSCO. Cutting speed should be approximately 17 - 19 m/min. If HSS drills are used, cutting speed should be approximately 3 – 5 m/min.

S690QL High Strength Quenched and Tempered Structural Steel

S690QL Flame-Cutting

The temperature of the material should be at least RT for flame-cutting. In addition, the following

preheating temperatures are recommended for certain plate thicknesses: For plate thicknesses over 40mm, preheat to 100°C and for thicknesses over 80mm, preheat to 150°C.

S690QL Welding

S690QL steel is suitable for all current welding methods. The temperature of the material should be at least RT for welding. In addition, the following preheating temperatures are recommended for certain plate thicknesses:

20mm – 40mm: 75°C

Over 40mm: 100°C

60mm and over: 150°C

These indications are standard values only, in principle, indications of SEW 088 should be adhered to.

The t 8/5 times should be between 5 and 25 s, depending on the welding technique used. Should stress relief annealing be necessary for constructional reasons, this should be done in the temperature range of 530°C-580°C

|

Welding Method |

Type of Electrode |

||

|

E-Hand |

FOX EV 85, FOX U 100 N OK 75.75 |

E11018-G E11018-M |

Böhler ESAB |

|

UP |

U 100-UP, NiCrMo 2,5-UP//BB24 OK Autrod 13.44/ OK Flux 10.62 |

EF6, F11A8-EM4-M4 |

Böhler ESAB |

|

MAG |

70-IG/M2 OK Autrod 13.29, OK Tubrod 14.03 |

ER110S-G ER100S-G, E110T-G |

Böhler ESAB |

Country of Origin :

Japan, Korea, China, UK, Denmark, Germany, French, Austria, Finland and Sweden.

Please send your valued inquiry to This email address is being protected from spambots. You need JavaScript enabled to view it. or contact us +604-2291331

Please note: the technical information above is for guidance only – for exact specifications please check with our sales team.

Tel : +604-229 1331

Tel : +604-229 1331 Fax : +604-229 3113

Fax : +604-229 3113 Email :

Email :