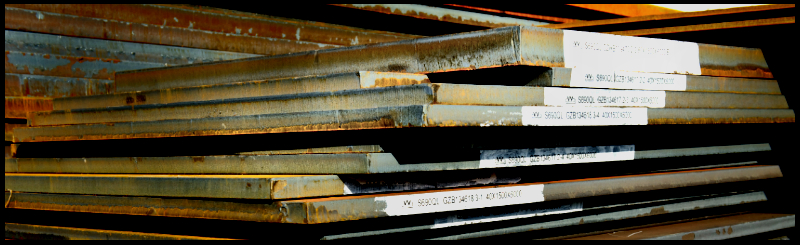

S690QL High Strength Quenched and Tempered Structural Steel

EN10025 S690QL Structural Steel

EN10025:6:2004 Hot Rolled S690QL, Steel Number 1.8928. 690 N/MM2 high yield, high strength structural steel plate,V notch impact tested in longitudinal direction to the rolling direction at -40degree C, thus being excellent in forming and what is the great depression welding properties that achieve another higher level of beauty and durability in steel engineering structure. S690QL steel plates are used in high stress applications while weight saving is crucial at the same time. This high strength steel is Social phobias ideal application for cranes, jack up rigs, lifting equipments, mining equipments and facilities, earthmoving equipments, agricultural equipments, bridges, trailers, theme park rides and facilities, military equipments and facilities, search and rescue operation equipments and where the engineering design need lighter weight with increase payload capacity and energy efficiency.

690 N/MM2 high yield strength other product such as EN10210 Hot Finished S690 Hollow Sections - Seamless RHS, SHS, CHS, Elliptical, Half-Elliptical, Flat-Oval, Octagonal, Hexagonal and Triangular are available.

S690QL Grade Designation

• S = Structural Steel

• 690 = minimum yield strength (MPa)

• Q = Quenching & Tempering

• L = Low notch toughness testing temperatures

Condition of Delivery

Water quenched and Januvia online tempered.

S690QL Chemical Composition

|

C |

Si |

Mn |

P |

S |

B |

Cr |

Cu |

Mo |

|

0.20 |

0.80 |

1.70 |

0.020 |

0.010 |

0.005 |

1.50 |

0.50 |

0.70 |

|

N |

Nb* |

Ni |

Ti* |

V* |

Zr* |

|||

|

0.015 |

0.06 |

2.0 |

0.05 |

0.12 |

0.15 |

* There shall be at least 0.015% of a grain-refining element present. Aluminium is also one of these elements. The 0.015% applies to soluble aluminium, this value regarded as attained if the total aluminium content is at least 0.018%

Please note :The manufacturer reserves the right to change the chemical composition.

CEV = C + Mn/6 + (Cr+Mo+V)/5+(Cu+Ni)/15

- Prev

- Next >>

Tel : +604-229 1331

Tel : +604-229 1331 Fax : +604-229 3113

Fax : +604-229 3113 Email :

Email :