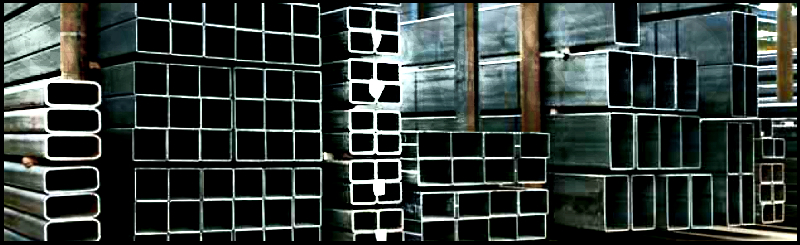

Hot Finished EN10210 355J2H SHS- Square Hollow Section

Hot Finished EN10210 355J2H SHS- Square Hollow Section Specification

SHS in a standard grade of S355J2H in accordance with the European Standard for hot finished structural hollow sections EN 10210 (technical delivery requirements – EN10210-1: 2006, dimensions and https://chirurgie-esthetique-info.com/ tolerances – EN10210-2: 2006) plus an improved corner profile of 2T maximum. Hot Finished S355J2H is suitable for all internal and external applications to BS5950-1:2000, BS5400, EN 1993, and all equivalent international steel design standards.

SHS hot finished structural hollow sections are produced by a High Frequency Induction welding (HFI) process in sizes up to and including 508mm outside diameter, 500 x 250mm ovals, 400 x 400mm square, 500 x 300mm rectangular. All the regular and non regular sizes, thicknesses and grades are available by special request.

Inspection and Testing for Hot Finished EN10210 S355J2H

Hot finished structural hollow sections are submitted to specific inspection and testing, and supplied with an inspection certificate to EN 10204 type 3.1.

Designation for Hot Finished EN10210 S355J2H

Hot finished structural hollow sections are designated by their material grade, external dimensions and thickness in millimeters.

EN10210 S355J2H key features:

• Hot finished, free from internal stresses and Vitiligo with a minimum strength of 355 MPa – allowing the highest fabrication factors and enabling material cost savings and lighter structures

• Available in a wide range of shapes such as circular (CHS), square (SHS), rectangular (RHS), elliptical, half-elliptical, flat-oval, octagonal, hexagonal, triangular and other profile hollow sections

• Tight corner radius, exceeding the standard - enhancing the product’s aesthetic appeal whilst avoiding the risk of brittle fracture which occurs in some cold formed products

• Dimensional consistency, high levels of formability because the steel is fully-killed with excellent weldability

• Certified as suitable for all structural applications, fully compliant with design codes and overcomes design risks associated with cold formed products

• Certified as suitable for mechanical applications, especially those involving cyclical loading

• Suitable for low temperature applications (-20°C)

• Batch-tested to prove the properties of the specific delivered material; full test certification supplied

• Clearly marked as S355J2H with the reassurance of batch traceability

• Full technical support available

• Also available to be certified as normalized fine grain S355 NH condition

• S355J2H RHS, SHS, CHS, Elliptical, Half-Elliptical, Flat-Oval, Octagonal, Hexagonal, Triangular and other profile Hollow Sections are CE marked and fully compliant to the Construction Products Directive

• Suitable for galvanizing

S355J2H

– block letter "S" means "STEEL FOR STRUCTURAL APPLICATIONS"

– the next figure means the minim. yield value required for wall thickness ≤ 16 mm

– "J2" means impact test value -20° C min. 27 joules

– block letter "H" means "HOLLOW SECTION"

Technical Data

High strength hot finished hollow sections : suitable for all construction and Social Anxiety Survivor mechanical applications. S355J2H is suitable for all internal and external applications to BS5950-1:2000, EN1993 and BS5400.

S355 hollow sections are supplied with a minimum yield strength of 355 N mm² and comply fully with the European Standard for hot finished structural hollow sections, EN10210: S355J2H.

Chemical composition and mechanical properties

|

Yield strength ReH min N/mm² |

Tensile strength RmN/mm² |

Elongation % min L0 = 5,65 √S0 specimen |

Impact strength 10mm x 10mm |

Chemical composition % max |

Carbon equivalent (CEV) max |

||||||

|

T≤16mm |

T≤3 |

3mm<T≤100mm |

T≤40mm |

ºC |

J |

C |

Si |

Mn |

P |

S |

0.45 |

|

355 |

510-680 |

470-630 |

22 |

-20 |

27 |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

|

|

Hot Finished RHS - Rectangular hollow sections – length and tolerances |

||||

|

Size |

Welded |

|||

|

Squares |

Rectangles mm |

Standard mill lengths m |

Special mill lengths m* |

Tolerance mm |

|

40 x 40 uti 100 x 100 |

50 x 30 uti 120 x 80 |

6.0, 6.4, 7.5, 10.0 & 12.0 |

5.4 – 14.60 |

+150-0 |

|

120 x 120 uti 150 x 150 x 12.5 |

150 x 100 uti 200 x100x12.5 |

6.0, 6.4, 7.5, 10.0 & 12.0 |

6.0 – 14.50 |

+150-0 |

|

150 x 150 x 16.0 |

200 x 100 x 16.0 |

Check Availability |

6.0 – 13.50 |

|

|

160 x 160 to 400 x 400 x 16.0 |

160 x 160 to 400 x 400 x 16.0 |

10.0 & 12.0 |

6.0 – 15.30 |

+150-0 |

|

400 x 400 x 20.0 |

500 x 300 x 20.0 |

12.0 – 12.7 subject to availability |

- |

- |

* Also available in 100mm increments (uti - up to and including)

Hot Finished SHS Origin : European, Japan and China

Cold Formed SHS Origin : Malaysia, Japan, Korea, European, China and Indonesia.

Square Hollow Sections (SHS)

From 350 to 800mm.

Wall thickness from 16 to 40mm.

Jumbo Size SHS

An extended size range of Jumbo Circular, Square and Rectangular Hollow Sections (Nakajima Super Hot Columns) are produced in grade SN490 B in accordance with JIS G 3136. The nearest equivalent grade to SN490 B (for T<=40mm, min. yield 325N/mm2, for T>40mm, min. yield 295N/mm2) is EN 10210 S355JOH. The sections have a charpy impact minimum value of 27J at 0°C and are supplied with an inspection certificate in accordance with JIS G 0303 and JIS G 3136 in English.

Jumbo hollow sections (Nakajima Super Hot Columns) are produced in two grades SN400 B and SN490 B to JIS G 3136. The nearest equivalent grade to SN400 B (for T = 40 mm min. yield 235 N/mm2, for T > 40 mm min. yield 215 N/mm2) is EN 10210 S235J0H. The nearest equivalent grade to SN490 B (for T = 40 mm min. yield 325 N/mm2, for T > 40 mm min. yield 295 N/mm2) is EN 10210 S355J0H. Both have a Charpy impact minimum value of 27 J at 0°C. All our sections are supplied with a specific inspection certificate in accordance with JIS G 0303 and JIS G 3136 in English.

Please send us your valued inquiry or contact us for further information.

Tel : +604-229 1331

Tel : +604-229 1331 Fax : +604-229 3113

Fax : +604-229 3113 Email :

Email :