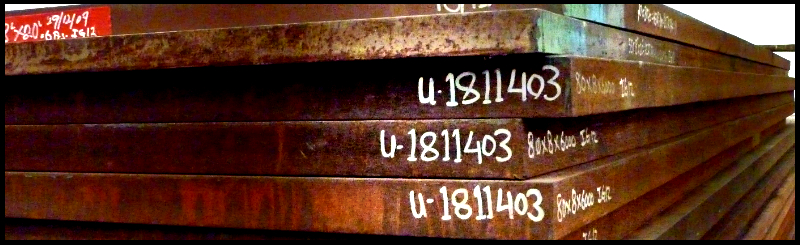

S355G10+N Z35 ; S355G10+M Z35 Offshore Steel Plate

We are a steel supplier which understand your offshore project requirement as we manage to decode your need and Erectialdisfunction want as we are fully experience in supplying offshore steel material in South East Asia Region. we supply high quality S355G10+N Z35 and S355G10+M Z35 from various origin such as Austria, Finland, Germany, UK, Japan, Korea and China.

Typical Application : Critical Joints

S355G10+N /+M offer great tensile and yield strength, common structural grade steel frequently used by the offshore industry. Both can be delivered as S355G10+N (N= Normalized) and SG355108+M (M= Thermo-Mechanically Rolled). As an offshore steel grade, S355G10+N and S355G10+M are used in a variety of applications including the building of offshore platforms.

S355G10+N and S355G10+M Close Equivalent Grade : Werkstoff 1.8813+N;1.8813+M;

Norsok M-120 Y20;

S355N4z;Y20 S355M4z

EN 10225 : S355 Grades Chemical Composition (ladle and product analysis / wt%) (1)

|

C max. |

Si |

Mn |

S max. |

P max. |

Cr max. |

Mo max. |

Nb max. |

V max. |

Ti max. |

Ni max. |

Cu max. |

Al(tot) |

N max. |

|

|

S355G10+M S355G10+N |

0.12 |

0.15/0.55 |

1.65 max. |

0.005 |

0.015 |

0.2 |

0.08a |

0.03 |

0.06 |

0.025 |

0.7b |

0.3 |

0.015/0.055 |

0.01 |

|

a.For t > 75 mm maximum Mo of 0.20% shall apply for +M condition. b. For t > 40 mm the minimum Ni content shall be 0.30%. |

||||||||||||||

|

Minimum Yield Strength / MPa |

Tensile Strength / MPa |

Minimum Average Charpy-V Impact Emergy / J@ -40ºC |

|

t ≤ 16 mm 355 16 < t ≤ 25 mm 355 25 < t ≤ 40 mm 345 40 < t ≤ 63 mm 335 63 < t ≤ 100 mm 325 120 < t ≤ 150 mm 320 (+N only) |

t ≤ 100 mm 470 - 630 t > 100 mm 460 - 620 (+N only) Minimum Elongation (5.65√s°) / % 22 |

50 mid-thickness test also required for t > 40 mm |

(1) Other restrictions apply beyond those shown.

Tel : +604-229 1331

Tel : +604-229 1331 Fax : +604-229 3113

Fax : +604-229 3113 Email :

Email :